HIGH-PRECISION AUTOMATION FOR THE TECHNOLOGIES OF TOMORROW.

BECAUSE TRUE INNOVATION DEMANDS MORE PRECISION THAN EVER BEFORE.

The market for high-precision automation systems is growing rapidly. More and more applications are pushing physical and technological boundaries – where micrometer-precise solutions are simply no longer sufficient. Our high-precision automation solutions and components help you realize motion, assembly, manufacturing, measurement, and inspection processes with positioning accuracies down to the sub-nanometer range. This allows your team to focus on what matters most – where conventional automation reaches its limits.

FROM MICROMETER

TO SUB-NANOMETER MOTION:

PRECISION FOR LIFE SCIENCE AND

SEMICONDUCTOR TECHNOLOGY.

Our core technologies represent precision that makes your processes faster, more stable, and more sustainable. With solutions ranging from micrometer to sub-nanometer accuracy, we are already creating the foundation for ultra-precise and reproducible manufacturing and positioning processes in life science and semiconductor technology. This opens up entirely new dimensions of technological performance in forward-looking key industries and disruptive technologies.

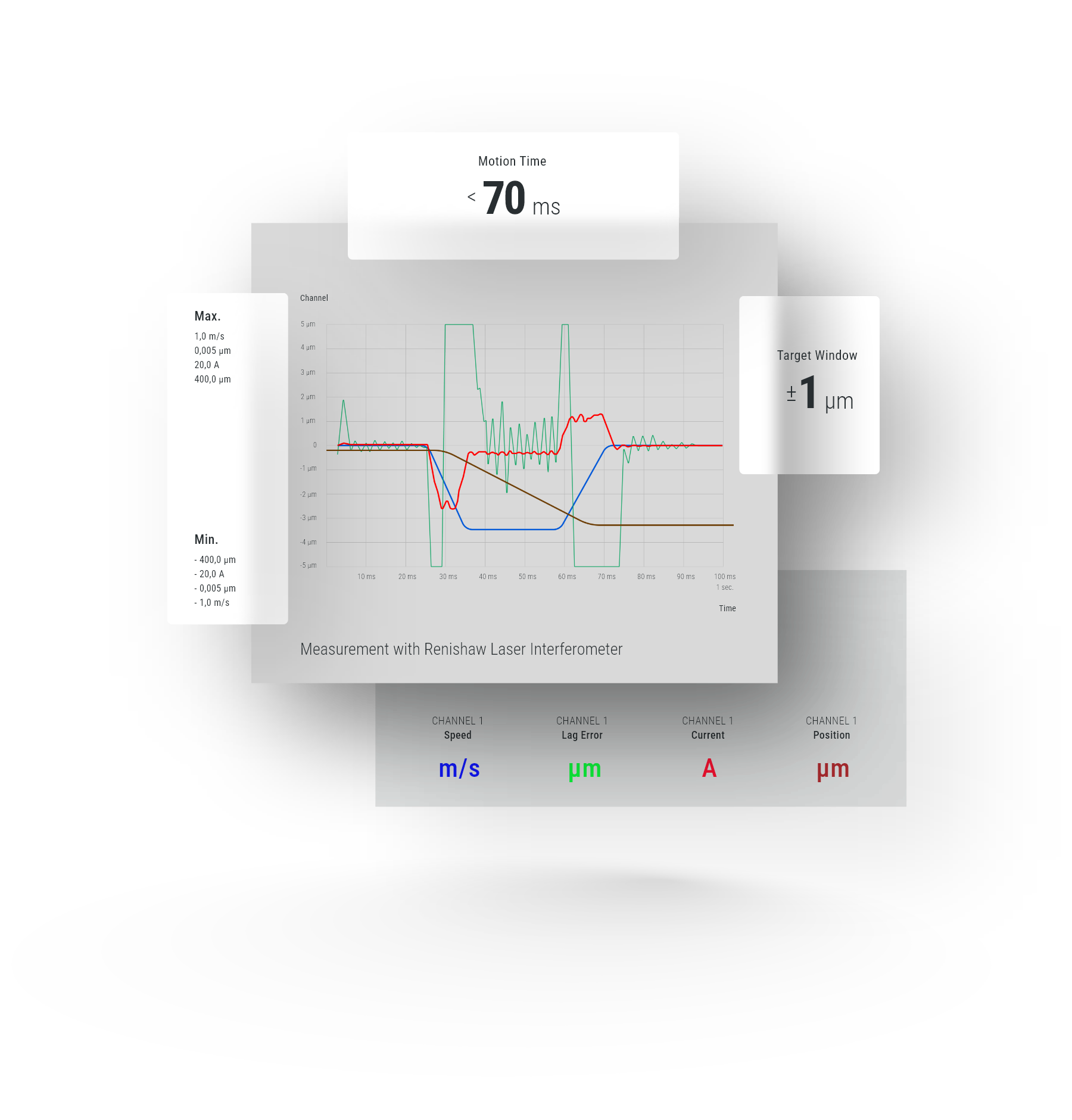

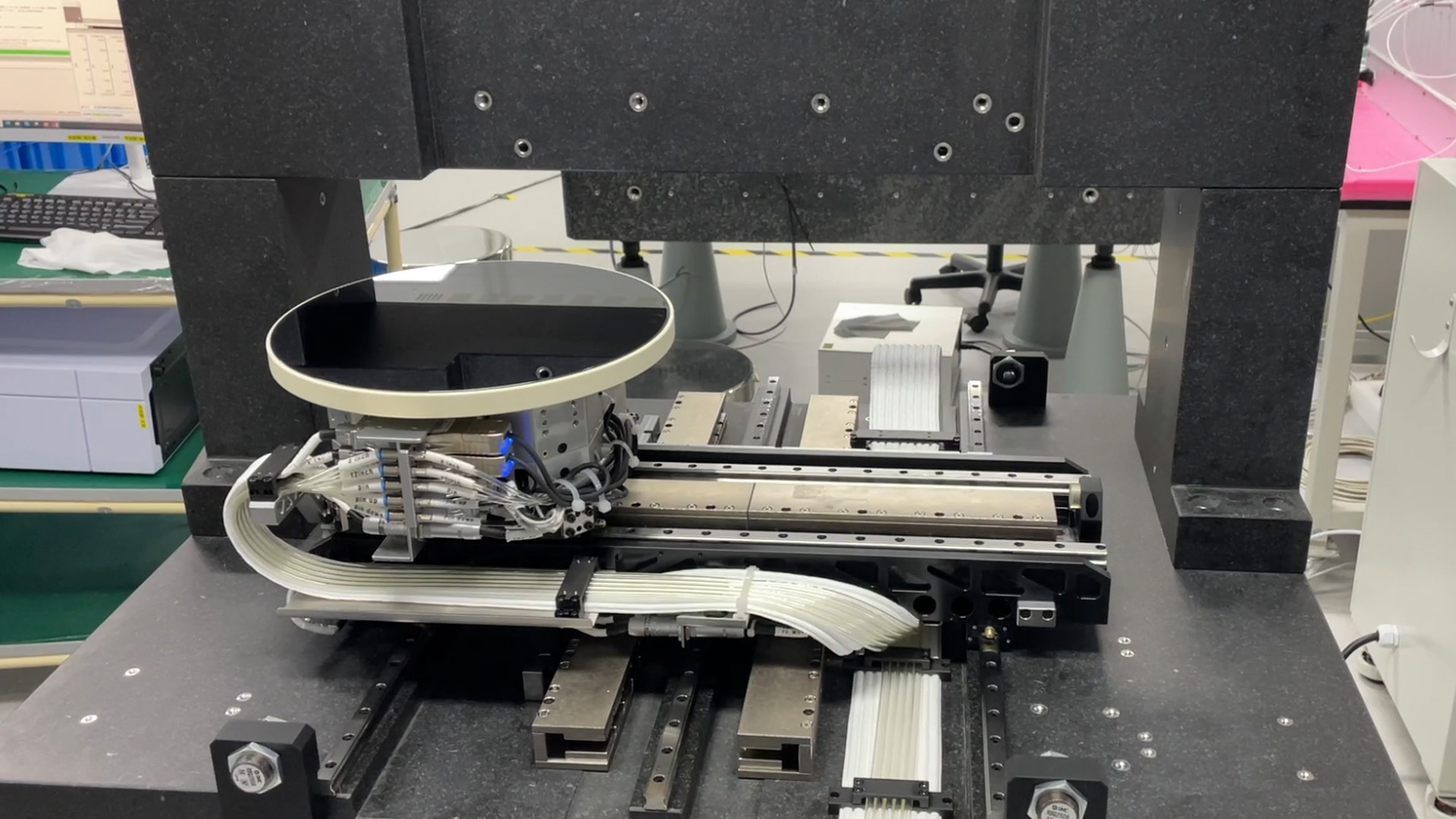

Real-World Example Application from Life Sciences

Precise system accuracies in fast step-and-settle operation

down to micrometer stability.

For demanding applications such as high-precision dispense processes in the life science sector, we have developed a system that enables travel ranges of 250 µm in less than 70 ms with jitter < ±1 µm.

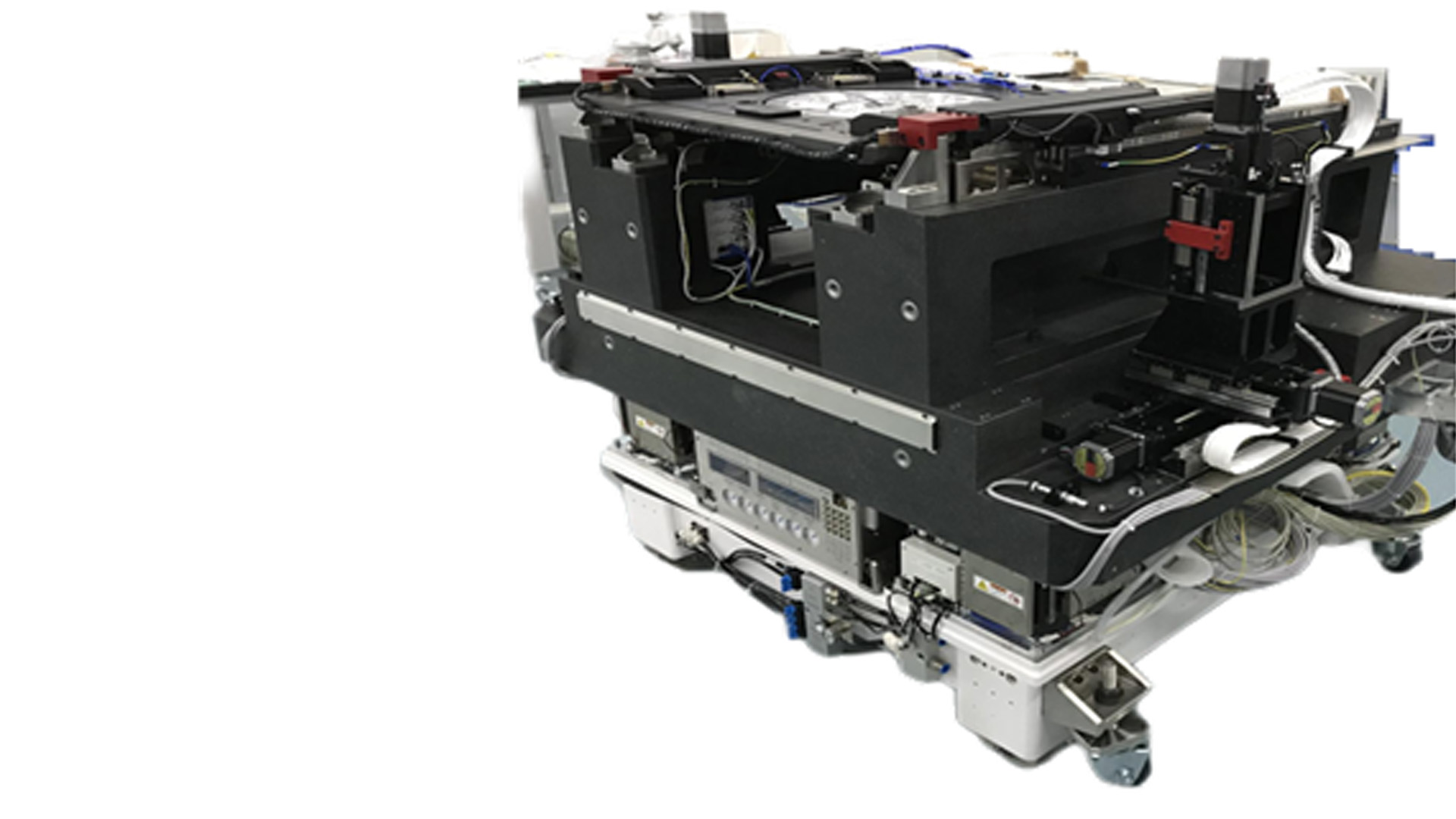

Real-World Example Application Semiconductor Manufacturing

Precise system accuracies in position stability

down to the nanometer range.

For the semiconductor industry, we developed a solution for an e-beam lithography application achieving a jitter of only 5 nm with less than 1 µT magnetic interference – establishing the foundation for ultraprecise, reproducible processes.

“Experience meets innovation, stability meets dynamics – apparent opposites united with power and balance. Because when precision defines innovation, it takes systems that continuously set new standards.

And partnerships that lead the way with experience, reliability, courage, and precision.”

Uwe WEISS, CEO WEISS World – on the technology partnership with YiNGUAN.

High-precision automation requires strong partnerships. Our technology alliance with YiNGUAN.

Accuracy requirements in focus from the start. Reproducible process precision without deviations

from target position or timing.

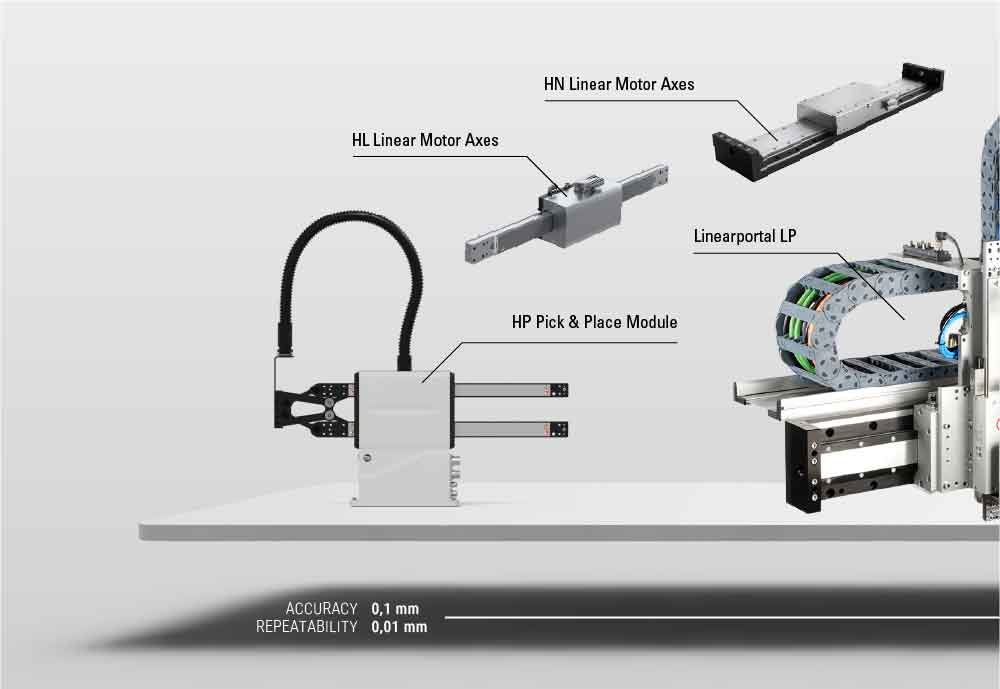

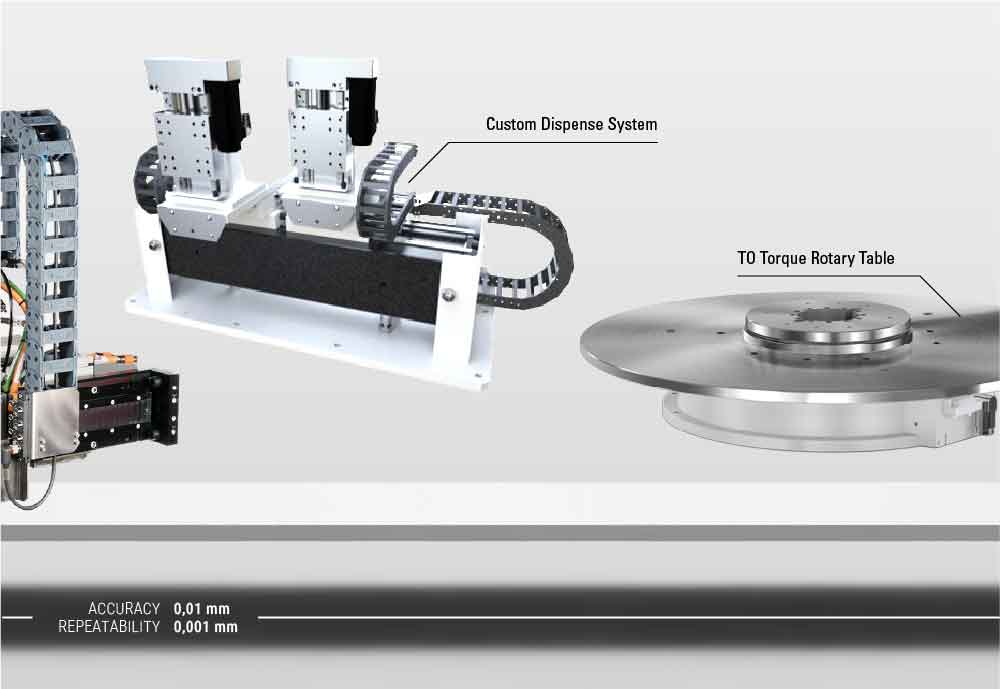

HIGH-PRECISION POSITIONING COMPONENTS.

Whether in semiconductor manufacturing, photonic systems, or lab automation – many disruptive developments are only possible when mechanical motion is precise, repeatable, and disturbance free. This is exactly where our technologies and products come in. High-precision positioning components form the foundation for ultraprecise motion in systems. Modular in design and seamlessly integrable, they enable motion, assembly, manufacturing, measurement, and inspection processes at the highest level – from research to mass production.

MAGNETIC DIRECT DRIVES.

Magnetic direct drives stand for maximum precision and dynamics in automation. Direct-driven linear and rotary systems enable virtually frictionless, highly dynamic movements with accuracies in the sub-micrometer range. Air bearing systems increase this performance even further: By combining direct drive and preloaded air bearings, they offer unparalleled smoothness, positioning, and running accuracy – perfect for the most demanding automation tasks.

Precision

Motion

Systems

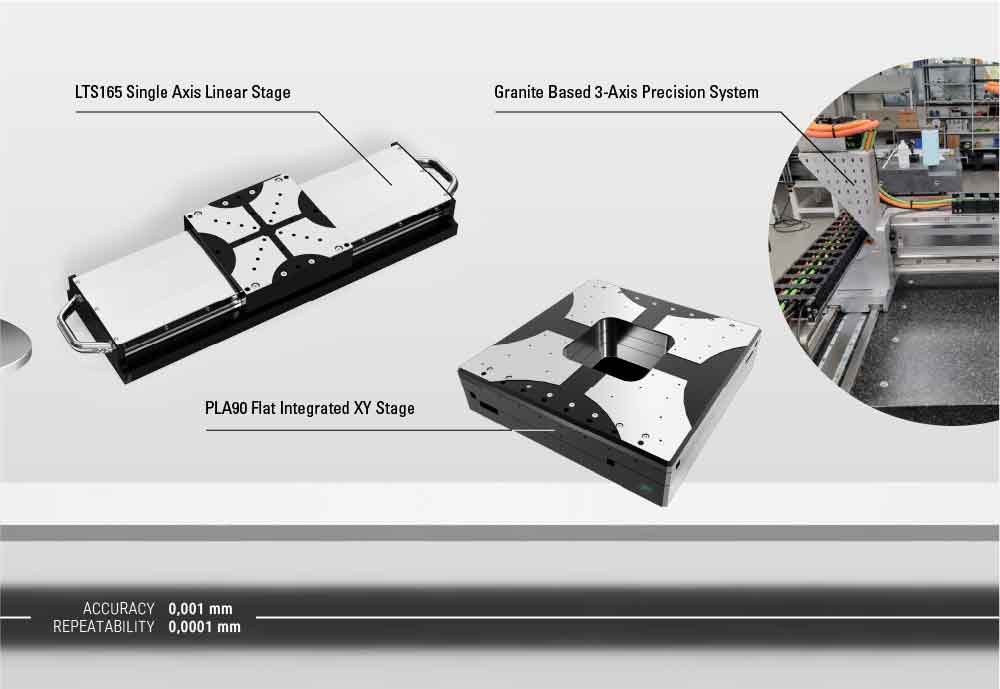

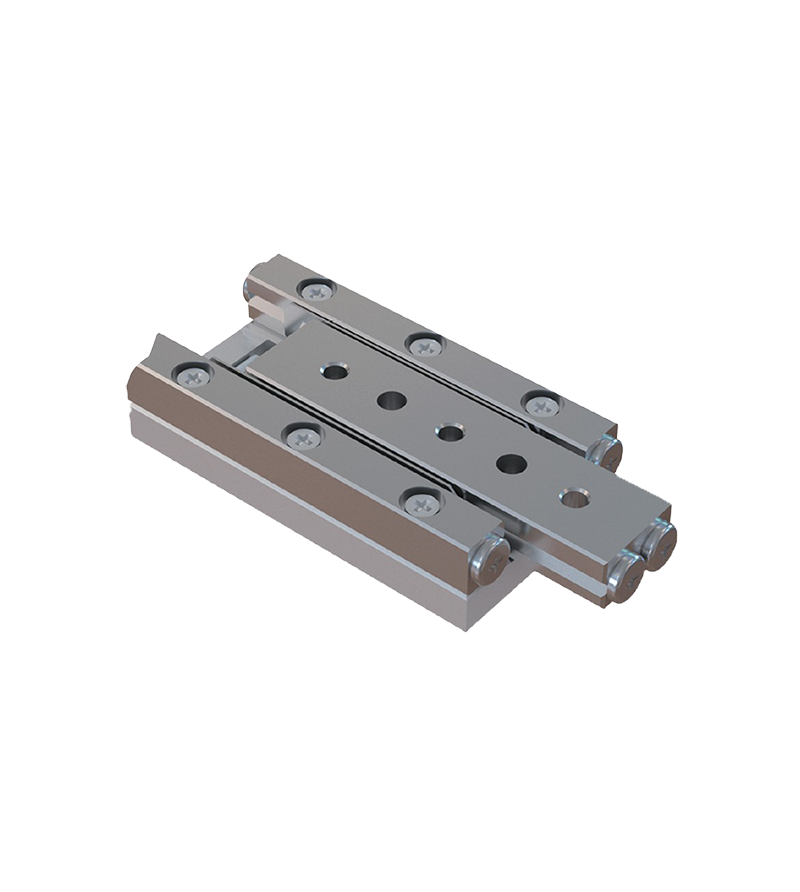

LTS165

Single-Axis Linear Stage

- Single axis

- Travel range: 100 – 600 mm

- Bidirectional repeatability: ±0.5 µm

- Max. load: 40 kg

Application areas:

laser cutting, semiconductor production, flat panel display manufacturing, industrial automation

Single-Axis Stage

Precision

Motion

Systems

MZH 400

Heavy-Load Z Stage

- Single Z-axis

- Travel range: 25 mm

- Bidirectional repeatability: ±0.5 µm

- Max. load: 40 kg

Application areas:

semiconductor production, flat panel display manufacturing, optical fiber alignment

SIngle-Axis Stage

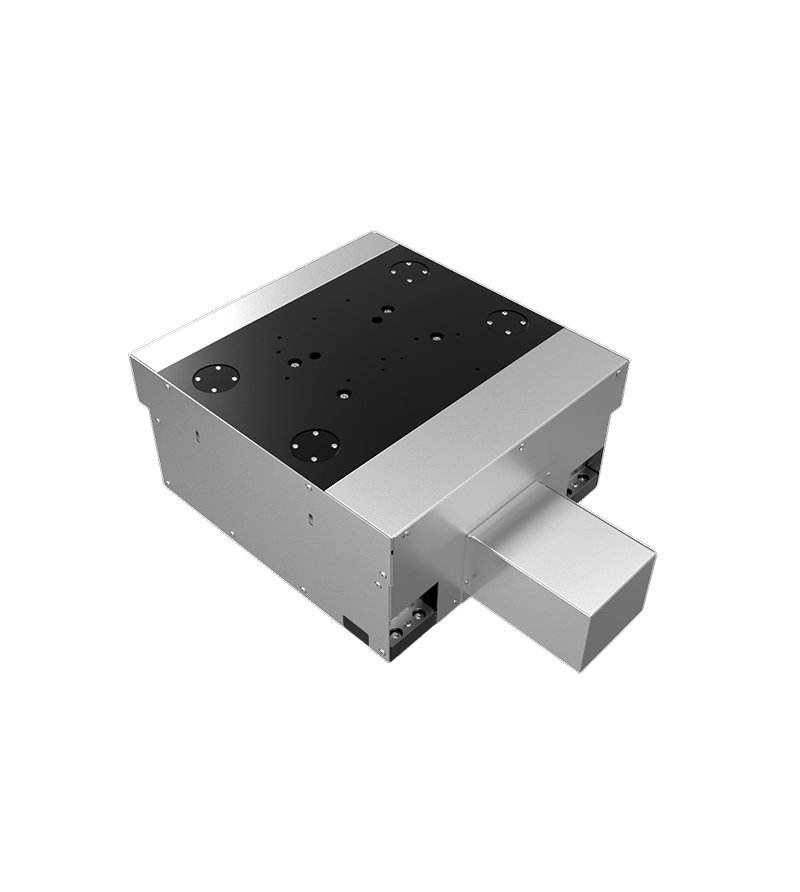

Precision

Motion

Systems

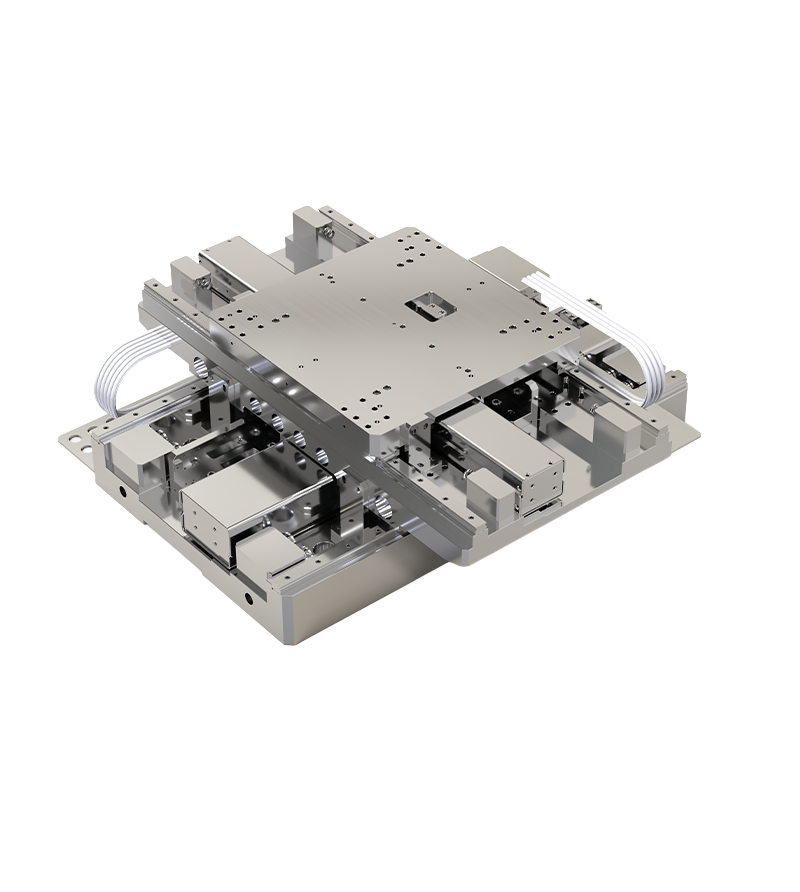

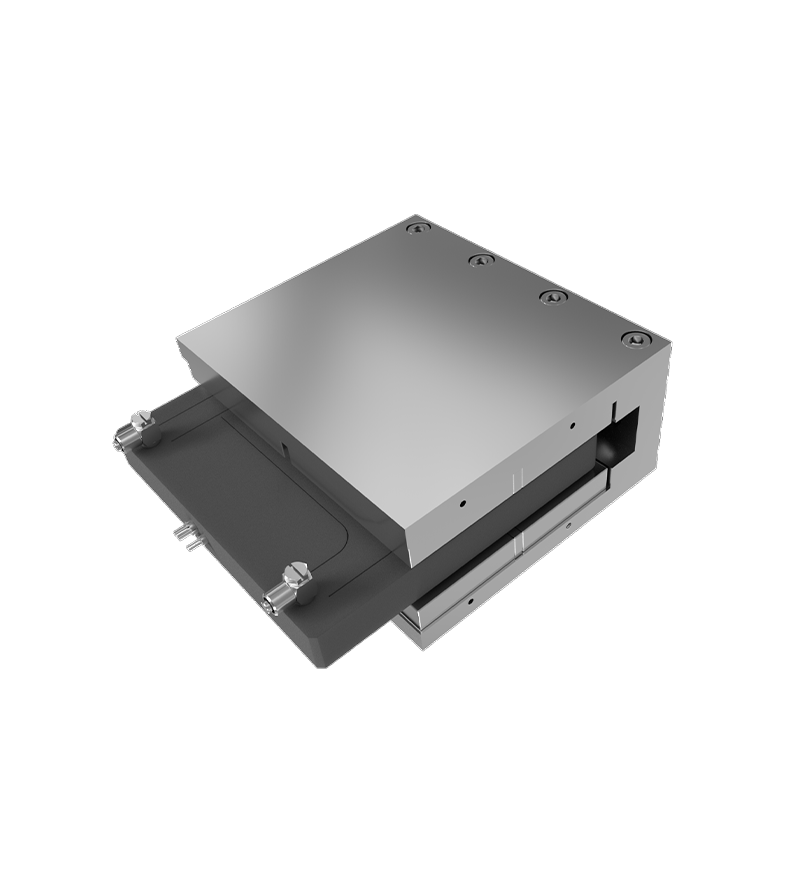

PL90

Flat Integrated XY Stage

- Non - contact direct - drive linear motor for high dynamic response

- Optical linear encoder for high precision

- High stiffness anti - creep cross roller guide

- Excellent positioning accuracy and dynamic performance

Application areas:

semiconductor production, flat panel display manufacturing, optical fiber alignment, biomedicine

XY Stage

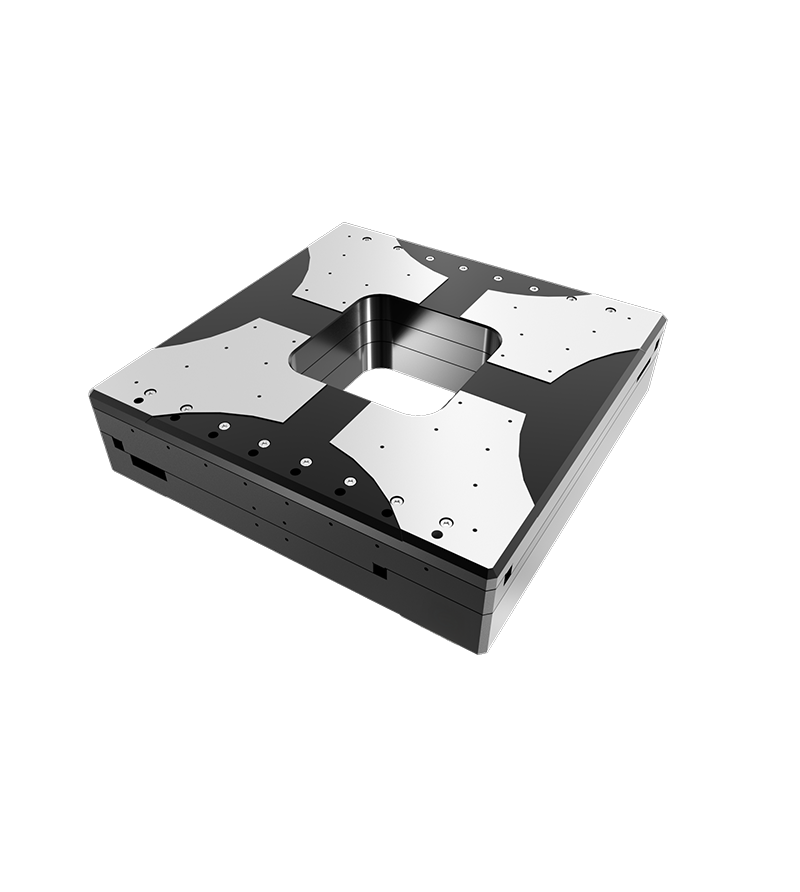

Precision

Motion

Systems

PLA90

Flat XY Stage with Aperture

- Non - contact direct - drive linear motor drive for high dynamic response

- Optical linear encoder for high precision

- High stiffness anti - creep cross roller guide

- Excellent positioning accuracy and dynamic performance

- Large hollow aperture

Application areas:

semiconductor production, flat panel display manufacturing, optical fiber alignment, biomedicine, double - sided processing, genetic detection

XY Stage

Precision

Motion

Systems

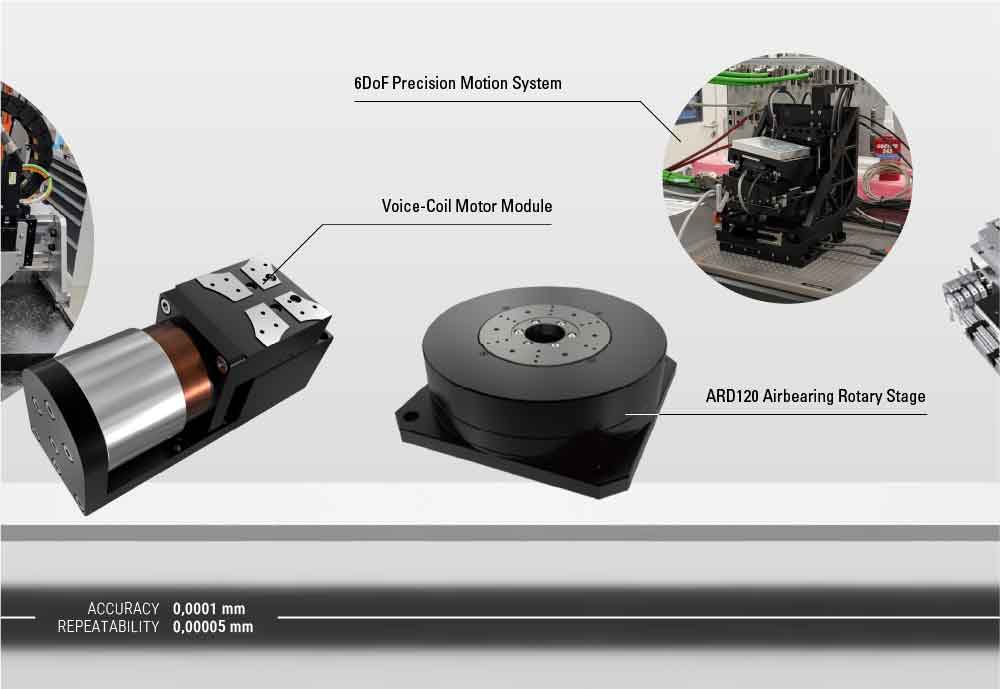

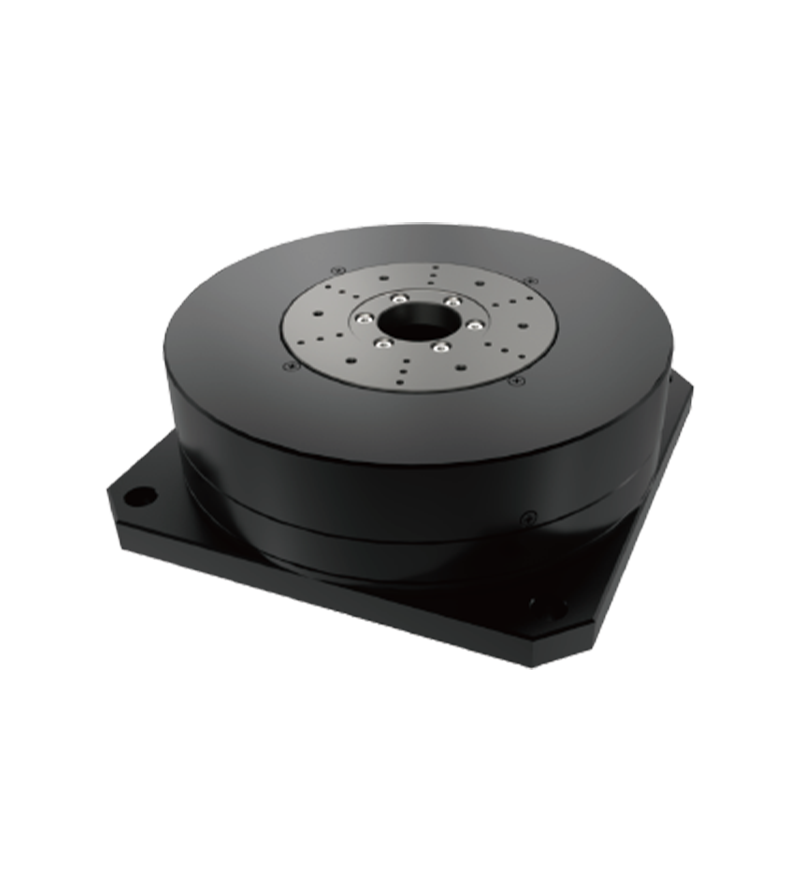

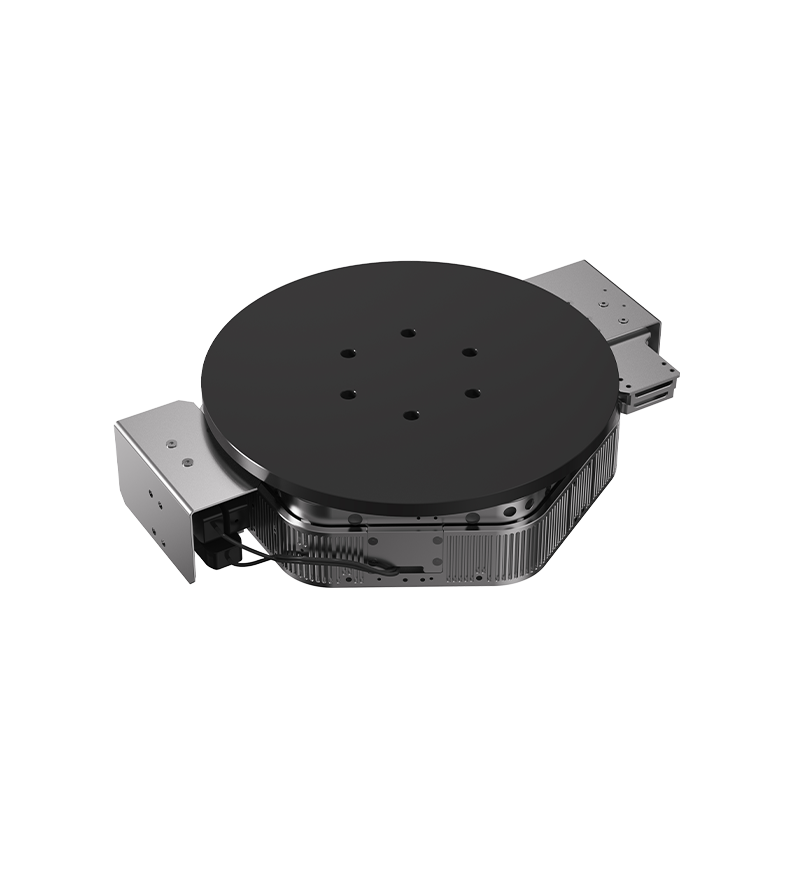

ARD120

Airbearing Rotary Stage

- Single Θ -axis, airbearing design

- Bidirectional repeatability: ±0.5 arcsec

- Diameter: 120 – 220 mm

- Hollow aperture: 10 – 50 mm

- Max. load Axial: 8 – 66 kg

- Max. load Radial: 4 – 36 kg

- Rotation velocity: up to 1,000 rpm

Application areas:

wafer inspection, high precision metrology, X-ray diffraction systems, optical inspection and manufacturing, MEMS/nanotechnology equipment manufacturing

Air-Bearing Stage

Precision

Motion

Systems

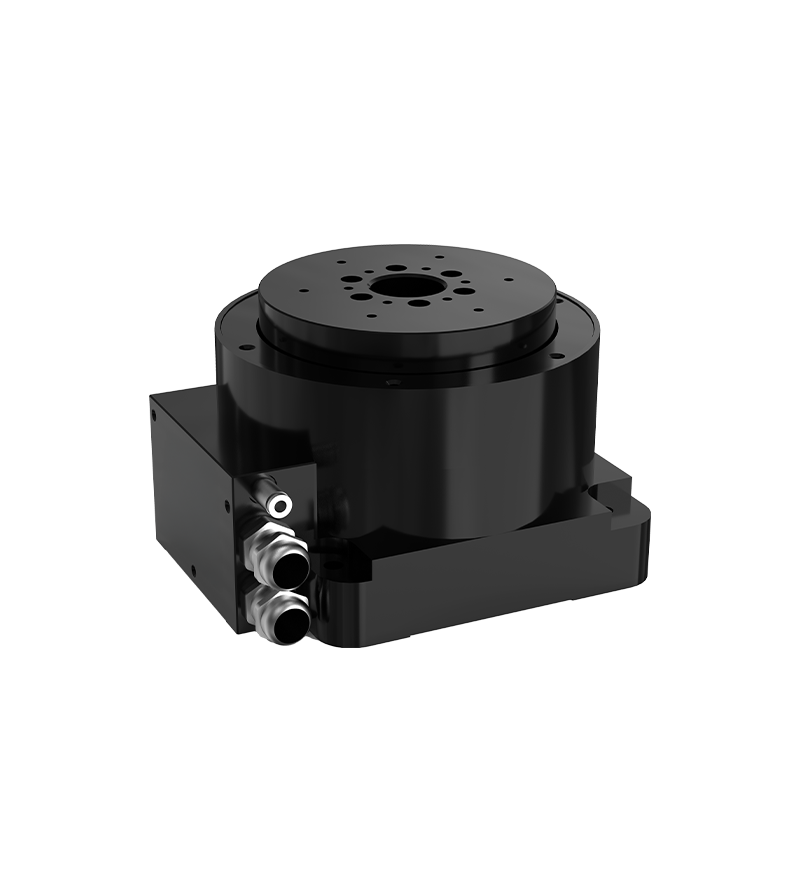

PART100

Airbearing Rotary Stage

- Single Θ -axis

- Airbearing design

- Bidirectional repeatability: ±1 arcsec

- Diameter: 100 mm

- Hollow aperture: 25 mm

- Max. load Axial: 53 kg

- Max. load Radial: 17 kg

- Rotation velocity: up to 600 rpm at 48V

Application areas:

semiconductor production, laser field

Air-Bearing Stage

Precision

Motion

Systems

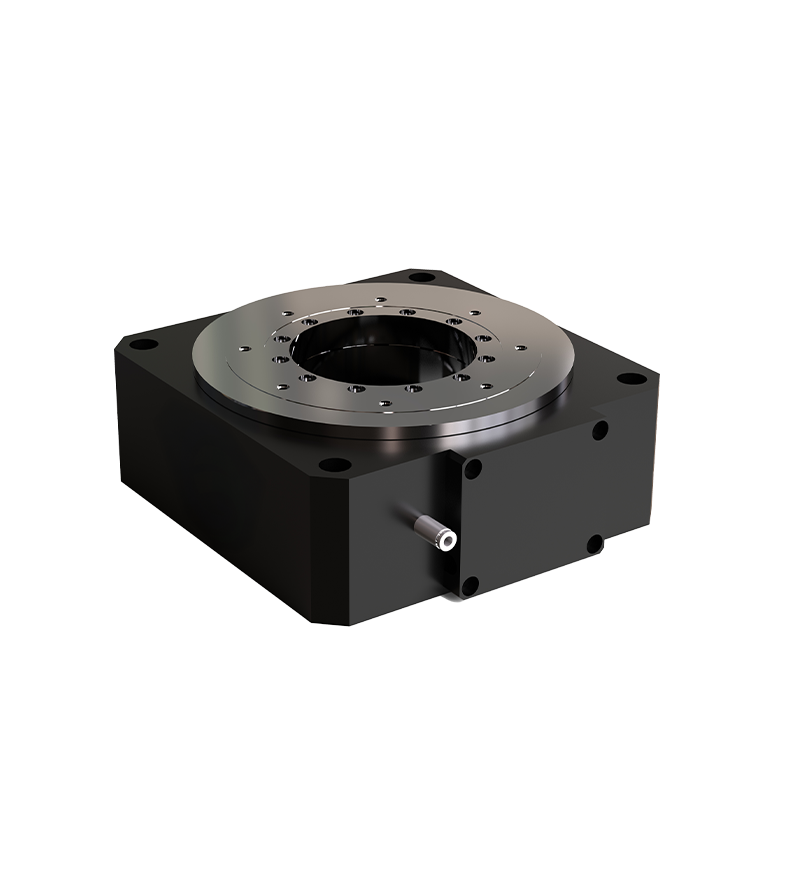

LART150

Air-Bearing Rotary Stage

- Single Θ -axis

- Air-bearing design

- Bidirectional repeatability: ±1 arcsec

- Diameter: 150 mm

- Hallow aperture: 75 mm

- Max. load Axial: 80 kg

- Max. load Radial: 30 kg

- Rotation velocity: up to 800 rpm

Application areas:

semiconductor production, laser field

Air-Bearing Stage

Precision

Motion

Systems

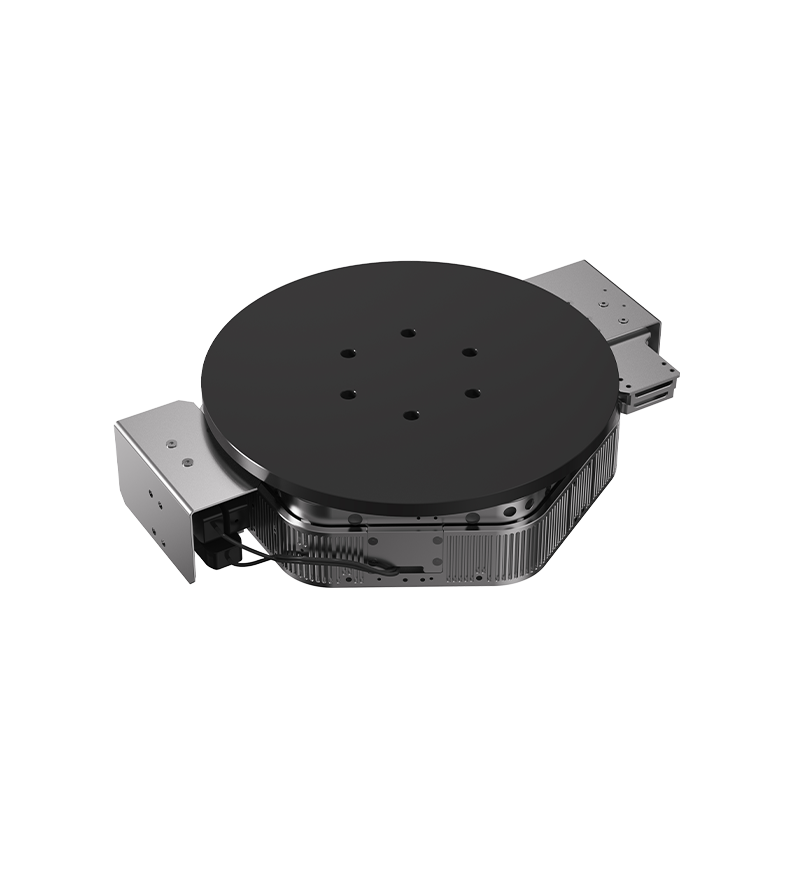

MZT90

Maglev ZΘ Stage

- Z and Θ -axis, 360° infinition rotation

- 12, 8, 6 inch wafer applicable

- Bidirectional repeatability: ±0.3 µm/1 mm (Z-axis); ±2 arcsec (Θ -axis)

- Z-axis straightness: 2 µm

- Vertical travel range: up to 30 mm

- Rotation velocity: up to 150 rpm

Application areas:

Wafer process control applications such as optical critical dimension metrology and thin film metrology; Wafer scribing, cleaning, and cutting

ZΘ Stage

Precision

Motion

Systems

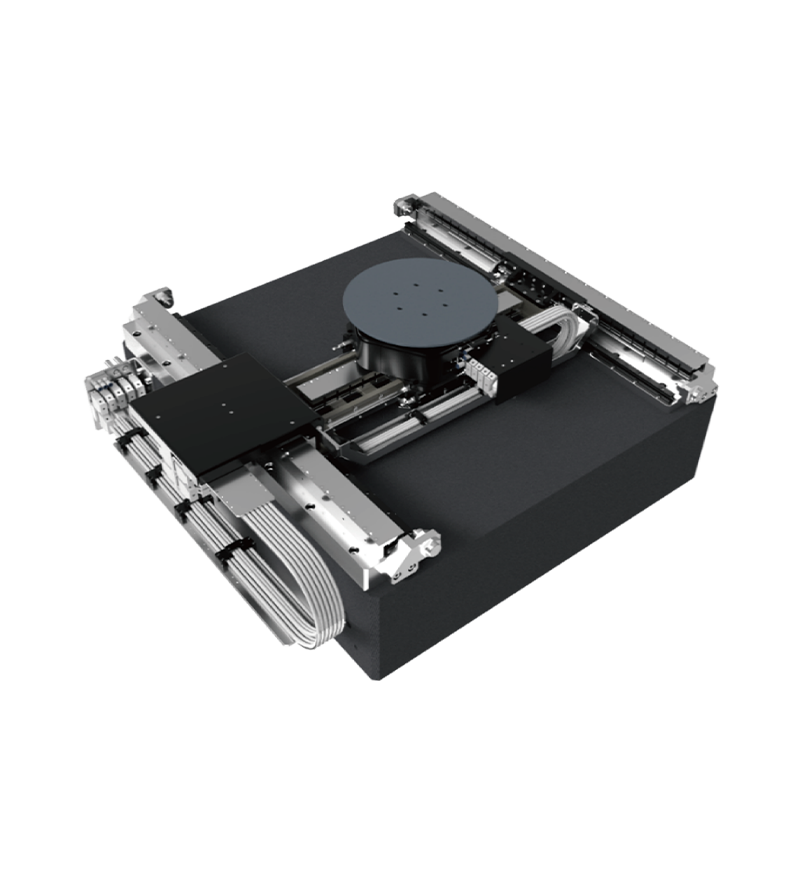

L4S210

Stacked XYZΘ Stage

- Stacked 3 - axis stage with orthogonality design

- Global flatness and straightness up to sub - µm level

- Consistent design of cable disturbing force

- Z - axis: Vertical magnetic levitation gravity compensation for high positioning accuracy; Vertical incremental encoder for up to 5nm resolution; Vertical mechanical travel up to 30mm

Application areas:

Wafer process control applications such as optical critical dimension metrology and thin film metrology, Wafer scribing, Wafer laser thermal annealing

Multi-Axis Stage

Precision

Motion

Systems

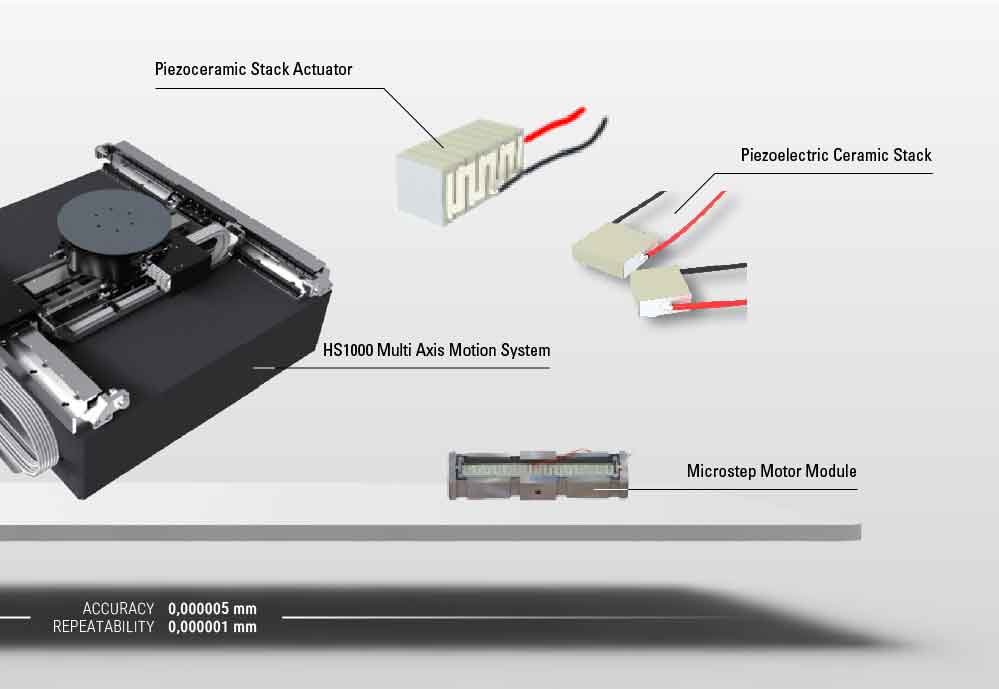

HS1000 METIS-

METIS Multi-Axis Motion System

- Integrated 5 - axis stage with orthogonality design

- X/Y axis: high - performance air - bearing guide for excellent dynamic flatness over the entire stroke

- Z - axis: Vertical maglev gravity compensation, vertical mechanical travel up to 30mm

- Θ - axis: rotation velocity up to 150 rpm (360° rotation)

Application areas:

Wafer process control applications such as optical critical dimension metrology and thin film metrology; Wafer scribing, cleaning, and cutting

Multi-Axis Stage

Precision

Motion

Systems

VLS200

XY Stage

- Suitable for ultra-high vacuum environments up to 10-5 Pa

- Vacuum linear motor drive for low outgassing rate, low heat generation

- Unique linear motor magnetic shielding design

- Optional non-magnetic materials, with overall magnetic leakage up to nT level.

Application areas:

electron beam inspection, vacuum bonding, scanning electron microscopy

Vacuum Stage

PIEZOELECTRIC DRIVES.

Thanks to their operating principle, piezoelectric solutions offer the possibility of performing the smallest movements with maximum accuracy in the sub-nanometer range. In combination with linear motor systems, this enables us to compensate for process deviations or to align the moving products with the highest precision. Piezo drives are also ideally suited for highly dynamic short-stroke applications such as autofocus systems in microscopy. In addition to their use as actuators (generating movement), piezo solutions can also be used as sensors (generating voltage).

Precision

Motion

Systems

Piezoelectric

Inertia Motor

- High-speed displacement

- High resolution

- Compact size

- Suitable for high vacuum environments

Application areas:

Optical stage, precision semiconductor equipment, precision medical testing equipment

Piezo Inertia Motor

Precision

Motion

Systems

Piezoelectric

Stepping Motor Stage – ZΘΘ

- Using piezoelectric stepping motor as motion actuators, high drive force, high holding force

- Multi-axis parallel control

- Millimeter-level large travel range

- Integrated high-precision encoder, nanometer resolution

Application areas:

structural levelling, non-magnetic environment, vacuum without heating environment, precision semiconductor equipment, precision medical testing equipment

Piezo Nano-Stage

Precision

Motion

Systems

A-136.50

Field Bus Piezo Amplifer

- 36-channels piezo amplifier, open loop

- Flexible options for different channels

- 0 ~ 150V voltage output, available for piezoelectric actuator products

- Support EtherCAT bus

Application areas:

optical lens adjustment, precision machining, precision semiconductor equipment, precision medical testing equipment

Piezo Motor Driver

Precision

Motion

Systems

C-90x Series

Servo Drive and Controller

- Multi-channel piezo motor servo control

- Flexible options for different channels

- Support incremental linear scale

- Host digital communication control

Application areas:

lens precision adjustment, electron microscope sample stage adjustment, semiconductor testing equipment, precision medical testing equipment

Piezo Motor Driver

Precision

Motion

Systems

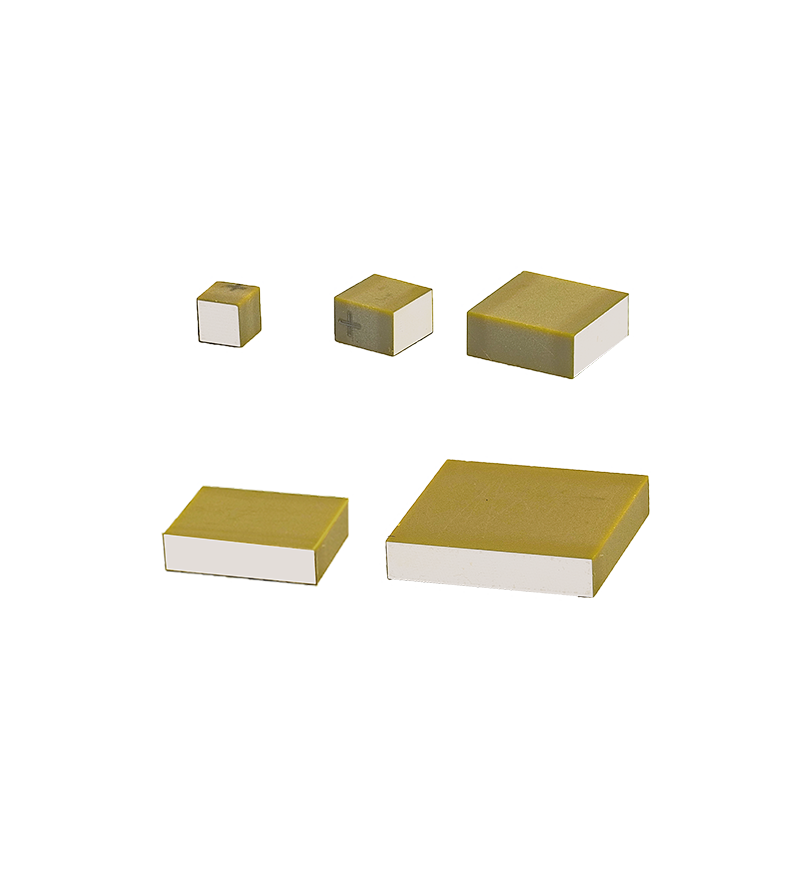

Piezo-Chip-

Actuator

- AC lifetime: 10⁹ cycles

- Operating voltage: -20 to +150V

- Microsecond-level response

- Vacuum compatible up to 10⁻⁶ Pa

- Sub-nanometer resolution

- Curie temperature of 230 °C

Application areas:

industrial automation, life Science, scientific research, semiconductor equipment, optical adjustment

Monolithic Piezo Actuator

Precision

Motion

Systems

A5 Series

Preloaded Piezo Actuator

- 1000 N thrust

- Piezoelectric ceramics with lifetime of one billion cycles

- Sub-nanometer resolution

- Simple structure, compact size

- Vacuum compatible up to 10⁻⁵ Pa

Application areas:

static and dynamic precision positioning, laser tuning, optical fibre positioning adjustment, micro - nano technology

Preloaded Piezo Actuator

VOICE COIL DRIVES.

Voice coil drive systems stand for outstanding precision and fast response times. These linear and rotary direct drives enable extremely dynamic movements with very high accuracy due to their low moving mass. Due to their design, these drives are suitable for movements with limited stroke (typically up to approx. 60 mm). In combination with guide systems and encoders, they offer excellent smoothness and repeatability, which are indispensable in sensitive industries such as semiconductor manufacturing, medical technology, and photonics. When combined with solid-state or flexure joints, short strokes can achieve highly dynamic, wear-free motion.

Precision

Motion

Systems

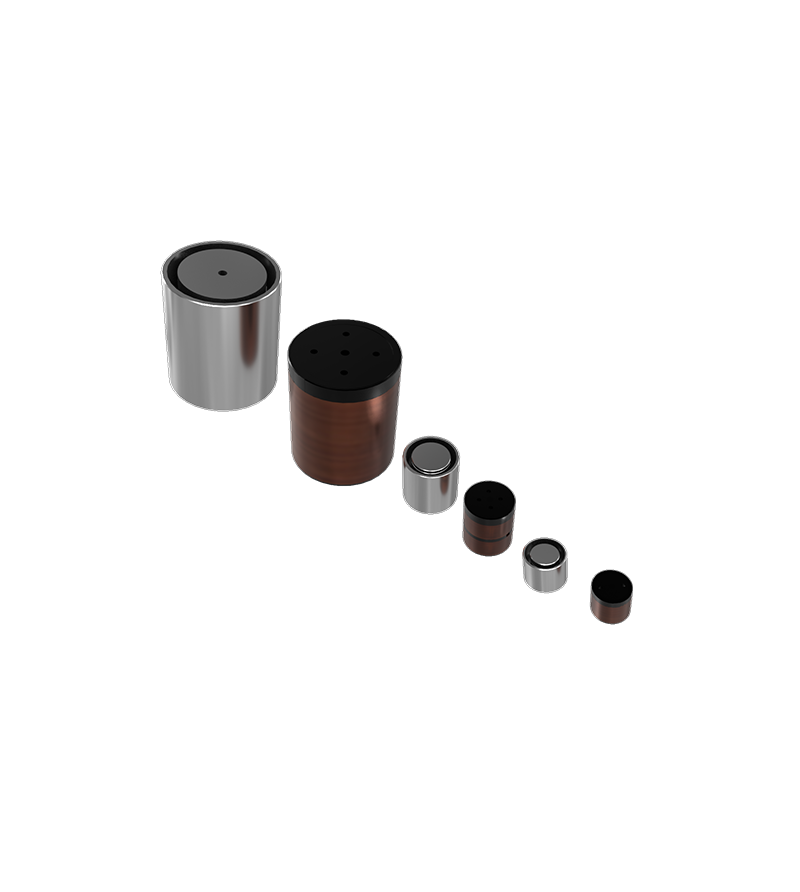

Cylindrical

Voice Coil Motor

- Compact design

- High velocity and acceleration

- High thrust, high dynamic response

- Excellent positioning accuracy up to nano level

Application areas:

ultra-precision positioning systems, semiconductor manufacturing, high-end machines, optical electronic microscopes, vibration platforms, active vibration reduction systems

Voice Coil Motor

Precision

Motion

Systems

Planar Water-Cooling

Voice Coil Motor

- Integrated water-cooling module, with high cooling efficiency, reliability, and long lifetime

- Extremely high thrust density, extremely low surface temperature rise, with higher continuous force and peak force

- Suitable for high vacuum environment

Application areas:

vacuum equipment, healthcare, semiconductor equipment, automotive

Water-Cooling Motor

Precision

Motion

Systems

Voice-Coil-

Motor Module

- High dynamic response, non - contact, direct drive voice coil motor

- High - precision optical linear encoder

- Excellent positioning accuracy and dynamic performance

- Modularized design, customized requirements accepted

Application areas:

healthcare, semiconductor equipment, automotive

Motor Module

Download all datasheets from our

portfolio with a single click – and explore

every product in detail.

Jetzt technisches Datenblatt herunterladen.

Geben Sie einfach Ihre E-Mail-Adresse ein –

das PDF wird Ihnen zur Verfügung gestellt.

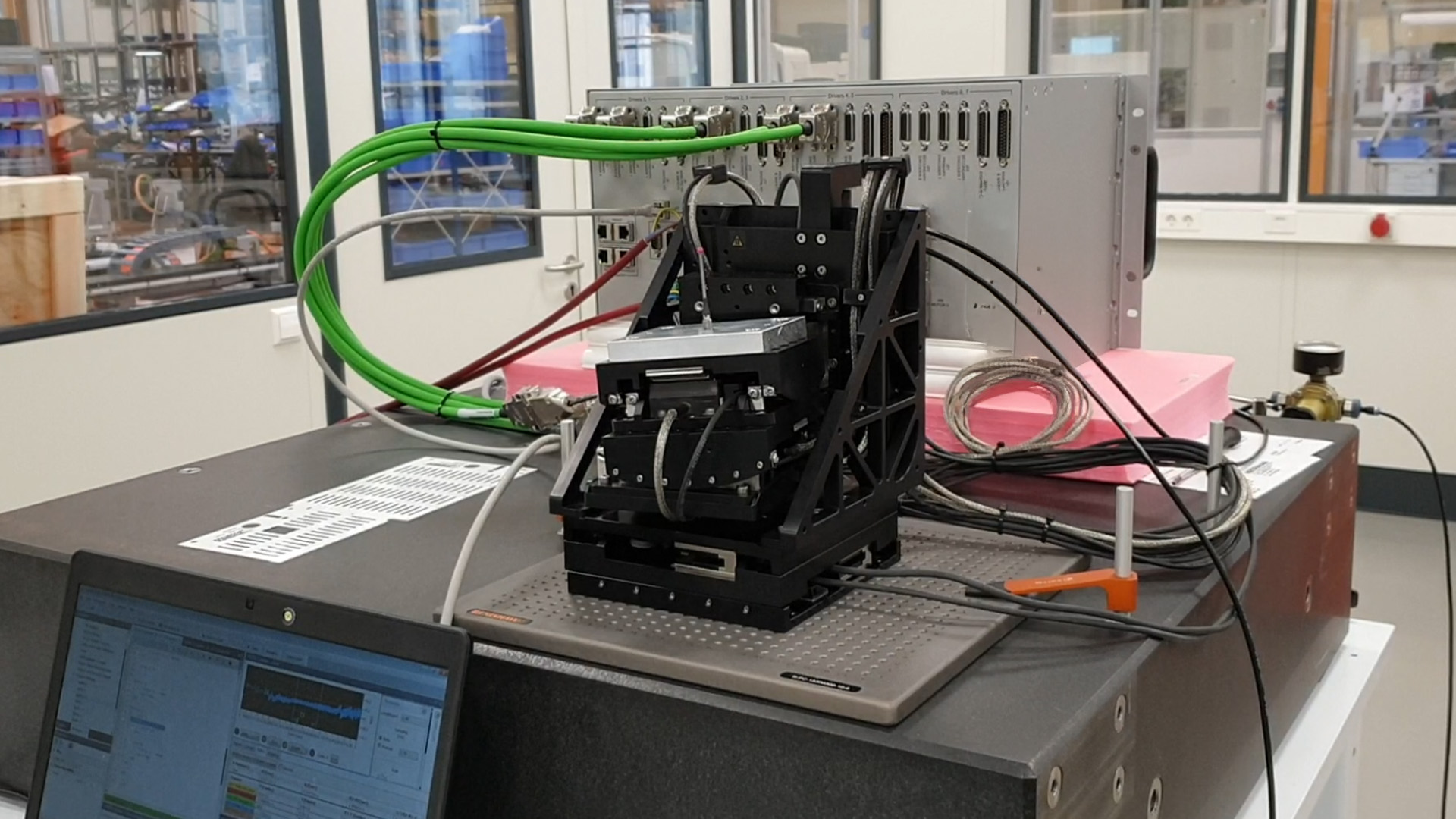

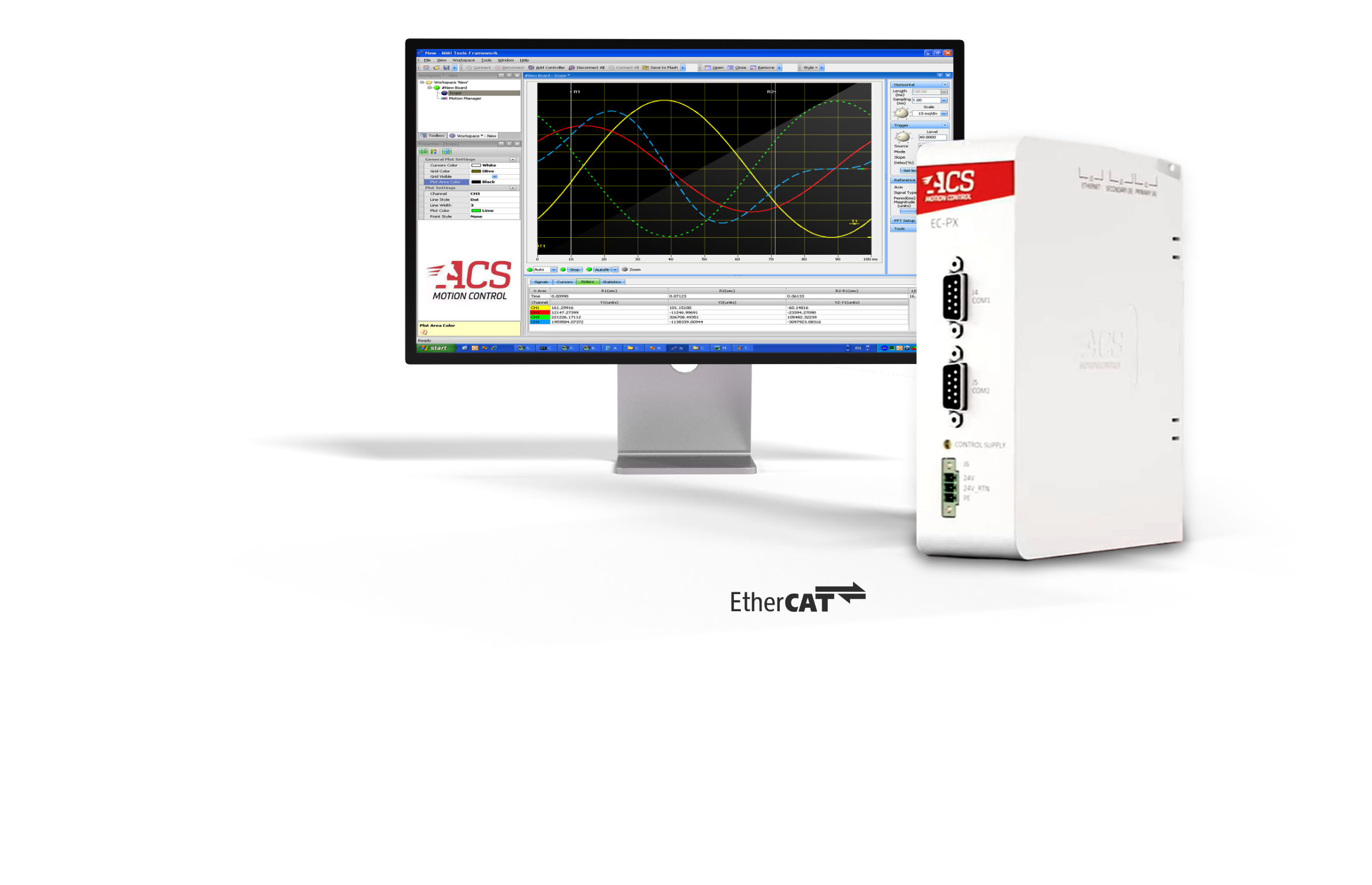

EASY INTEGRATION AND

MAXIMUM PERFORMANCE.

Precision requires not only excellent mechanics but also sophisticated control technology and software. Only by considering the overall system can the best results be achieved – ultraslow movements at constant velocity, minimal path deviations, or absolute positional stability – the motion control solutions from ACS offer the highest resolution, dynamics, deterministic performance, and nanometer-level trajectory control and are perfectly adaptable and integrable.

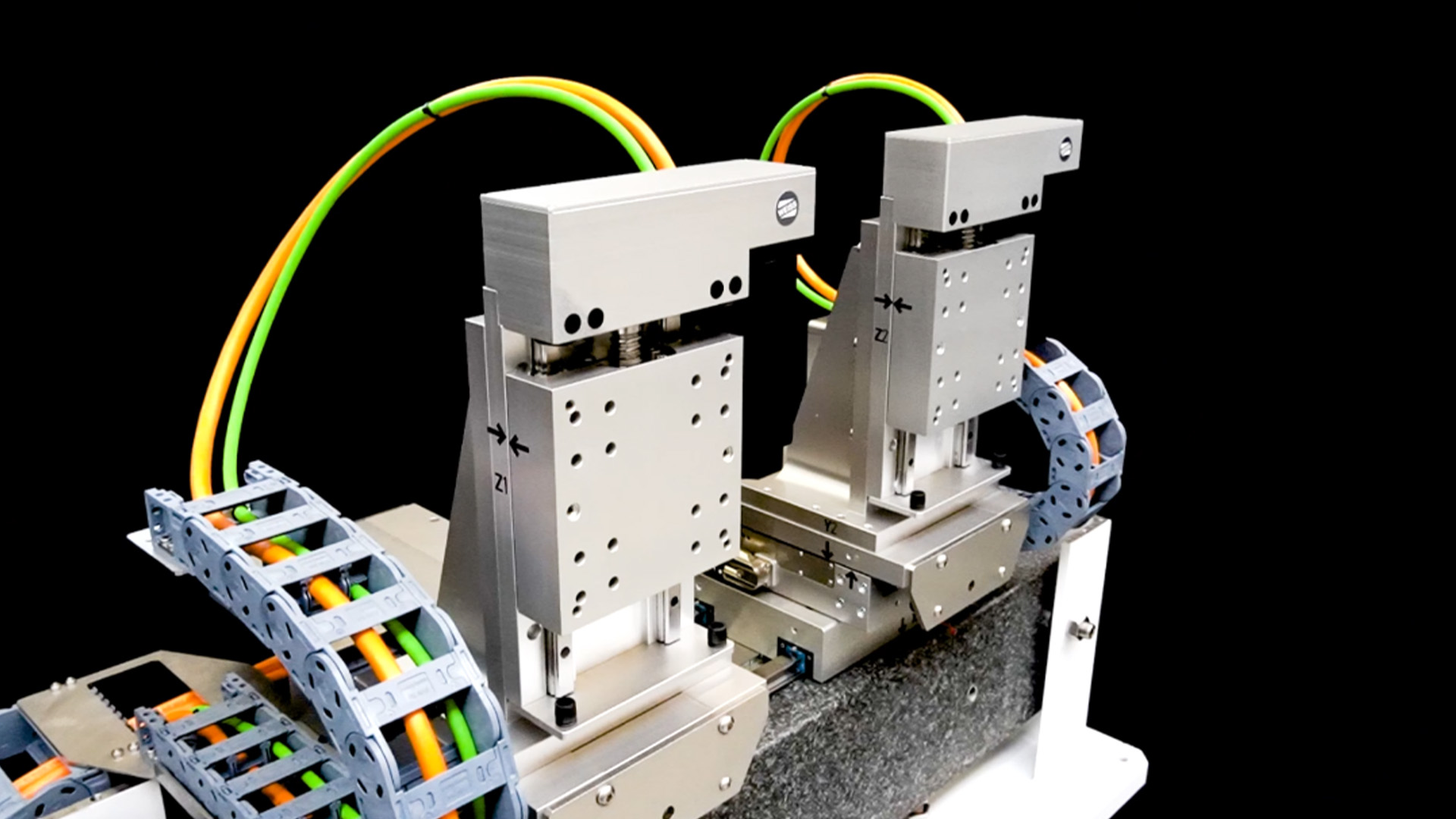

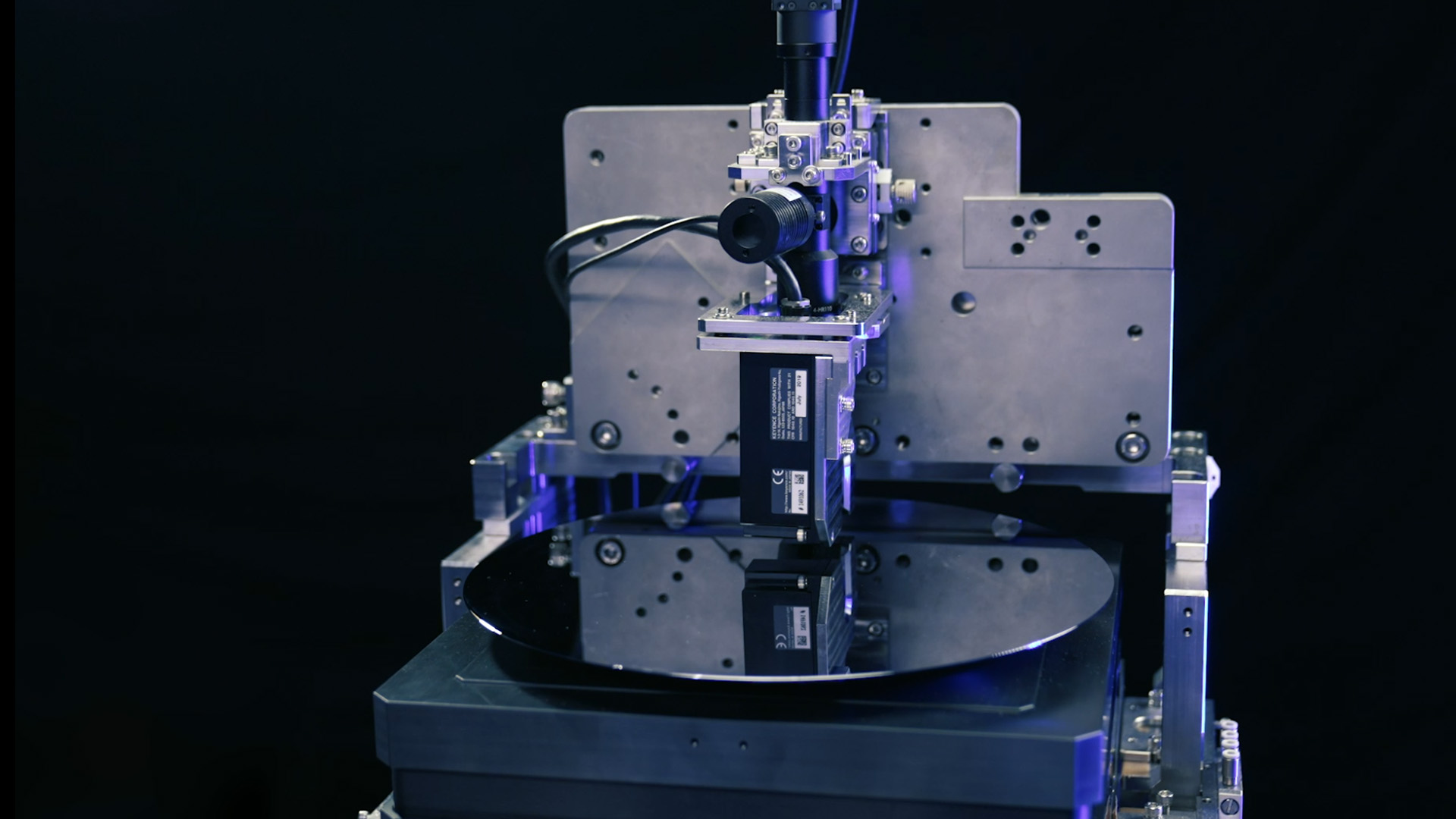

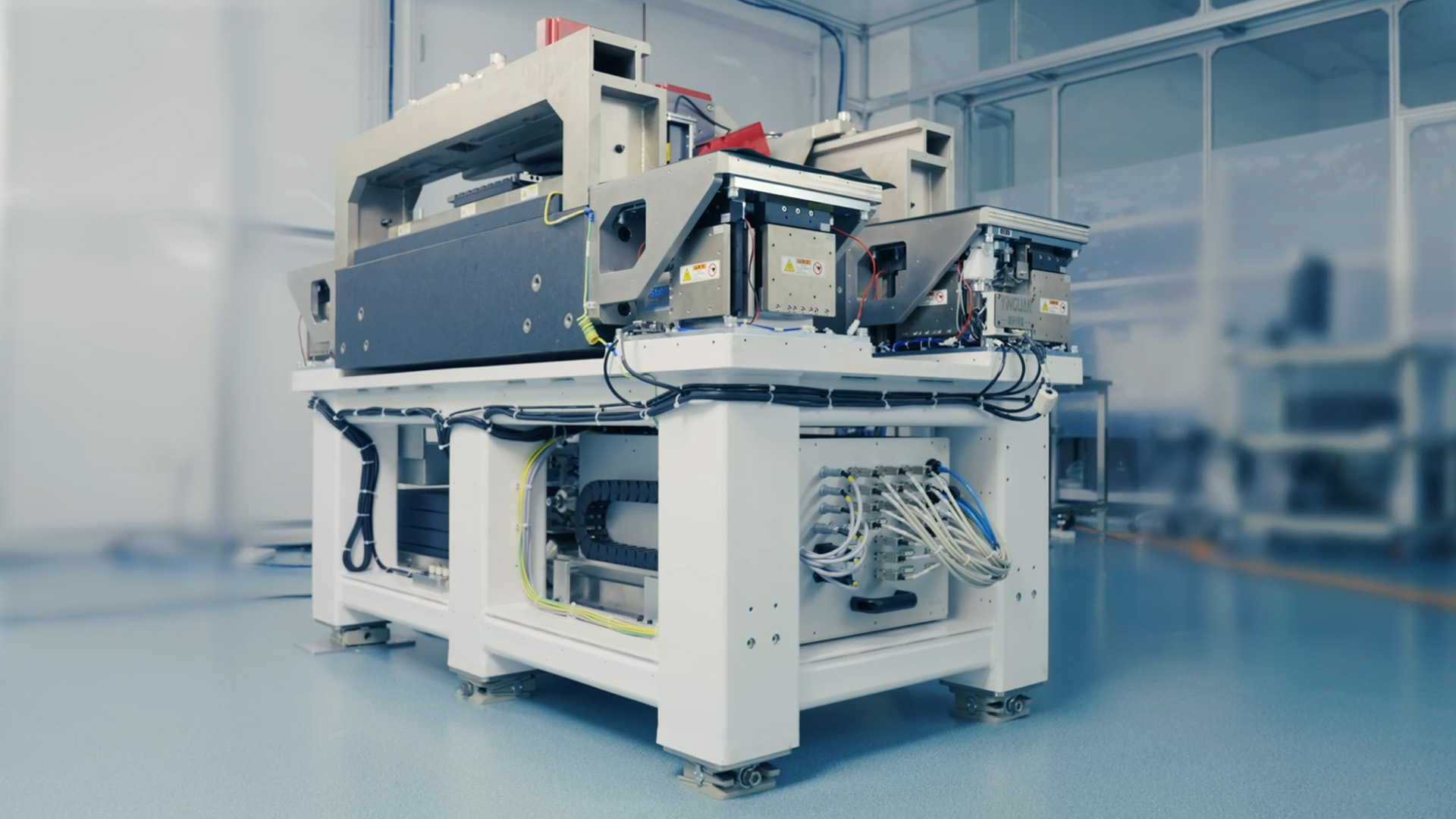

CUSTOMIZED MOTION AND POSITIONING SYSTEMS.

Developing customer-specific systems is one of our core strengths: Individual solutions that seamlessly integrate into your processes accelerate automation in key industries such as lithography, wafer inspection, micro-assembly, or optical alignment – laying the foundation for tomorrow’s technologies. Our high-precision motion and positioning systems result from the perfect interplay of our own precision components and technologies, intelligent control technology, and decades of engineering experience – from single-axis to complex multi-axis systems with integrated motion control.

Got Questions?

We Deliver

Precise Answers!

The partnership with YiNGUAN offers you clear advantages: faster innovation, shorter development times, and direct access to specialized know-how. Our global system expertise, application experience, engineering capacity, and worldwide sales and service network are optimally complemented by YiNGUAN’s expertise in precision technology and cutting-edge components.

YiNGUAN’s expertise is a perfect technical match for the already provided customer-specific solutions by WEISS, enabling us to offer economical solutions across all accuracy classes.

You benefit from an expanded product portfolio, faster availability, and a combination of internationally proven technology and local engineering support at a competitive price. Both single units and volume production can be offered economically and with short development cycles.

We support all areas of key technologies in high-precision and scalable automation with motion systems ideally suited for wafer inspection, lithography, packaging, micro-assembly, micro-laser processing, or optical alignment.

Yes, WEISS offers a comprehensive global service and support network in Europe and North America. For the Asian market, we work closely with Yinguan to provide optimal support for international projects.

Our sales team is happy to personally assist you with any questions regarding products, systems, and solutions. Contact us directly for Europe: franz.oebels@weiss-world.com and for North America: peter.fiouzi@weiss-world.com.

Book an appointment with our experts and get an exclusive insight into our systems and solutions. We are here for you.

- Franz Oebeles, Vice President Precision Systems at WEISS World

- Connect mit Franz Oebles

Let’s Get Started. We’re Always Ready.

Whether you want an exclusive demo, have a question about our systems, or want to discuss your application, we’re here for you. Connect with our experts today and discover how WEISS precision solutions can accelerate your innovation.